|

Description |

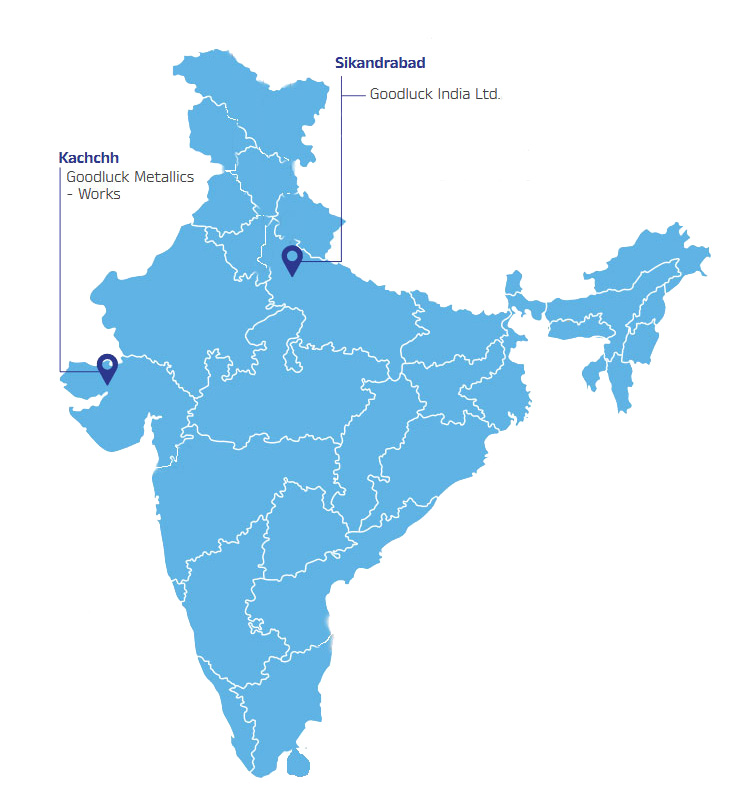

Sikandrabad (Delhi NCR) |

Goodluck Metallics (Bhuj, Gujrat) |

|---|---|---|

|

Total Area in Sq mtrs |

45000 |

5,50000 |

|

Covered Shed Area |

38000 |

50000 |

|

Trial Assembly & proto type area (Mtr x mtr) |

200 x 15 |

130 mtr x 20 mtr – 2 nos Open Area : 400 Mtr x 30 mtrs |

|

Galvanising Bath |

10.1 x 1.5 x 2.5 |

Closed Bath only for Pipes |

|

Blasting Painting facility |

120 x 10 200 x 100 |

100 x 16 20 x 20 |

|

Area |

Dimension |

Nos |

|---|---|---|

|

Fabrication Area |

||

|

Covered Shed 1: |

One |

|

|

Covered Shed 1 : |

276 mtr x 24 mtr |

One |

|

Covered shed 2: |

90 mtr x 24 mtr |

One |

|

Covered Shed 3 : (Under construction) |

235 mtr x 20 mtr |

One |

|

Finishing Area |

||

|

Blasting shed- 20 mtr x 16 mtr Three Booths |

20 mtr x 16 mtr |

Three Booths |

|

Painting shed 125 mtr x 20 mtr One |

125 mtr x 20 mtr |

One |

|

Trial assembly area |

130 mtr x 20 mtr |

One |

|

Open Area for Trial Assembly |

230 mtr x 20 mtr |

One |

|

Open Area for Further Development |

||

|

Open Area for New development |

330 mtrs x 200 mtrs |

One |

|

Crane and Handling Facility |

||

|

EOT Crane in Shed 1 |

25 MT – 3 no. |

|

|

EOT Crane in Shed 2 |

15 Mt – 2 no |

|

|

Goliath Crane in Shed 3 |

40 Mt – 1no. 20 Mt – 1 noo |

|

|

Hydra |

10 nos |

|

|

Mobile crane |

300 MT – 2 no. |

|

|

Manlift |

2nos |

|

|

Process |

Installed |

Capacity |

|---|---|---|

|

Cutting |

Multi torch Oxyfuel CNC Cutting 4 mtr x 14 mtr Multi Torch Oxyfuel CNC Cutting 3 mtr x 14 mtrs Multi Torch Plasma / Oxyfuel CNC Cutting 4 mtr x 14 mtr |

3000 MT |

|

Drilling |

High Speed Plate drilling M/c – 1no. Radial Drill machines – 3 nos |

6000 holes/day + 8000 holes/day |

|

Welding – SAW |

Gantry type Double Boom CNC SAW- 2 no Portable Type SAW CNC machine - 12 nos |

50,000 m per month |

|

Welding GMAW |

IGBT based welding machines - 20 nos |

15,000 mtr per month |

|

Straightening Machine |

Roller hydraulic based straightening machine – 1 no |

2500 MT per month |

|

End Face Milling Machine |

Vertical and horizontal milling machine |

2500 MT per month |

|

7 AXIS Drilling machine |

2 nos Special High Speed 12 axis and 6 axis machine. |

1000 MT per month |

|

Trial Assembly |

2 spans of 130 mtr each at one time |

|

|

Blasting |

Blasting shed with reclaimer Blasting guns – 8 nos. Hopper – 8 nos |

2 spans of 100 mtr each at one time 2500 MT per month |

|

Metallizing |

Oxygen based machines – 2nos Air based machines – 4 nos |

1200 sq mtrs a month |

|

Painting |

Closed shed = 2 nos. Painting guns |

2000 sq mtr a month |

|

Area |

Dimension |

Capacity of production |

|---|---|---|

|

Covered Shed and facility |

||

|

Total Area covered under shed Fabrication |

196 mtrs x 25 mtrs 90 mtr x 20 mtr 64 mtr x 20 mtr |

2500 MT per month |

|

Blasting and painting Area |

60 mtrs x 20 mtrs 40 mtrs x 30 mtrs |

|

|

Trial Assembly Area for Bridges |

||

|

Open web span |

70 mtr x 15 mtr |

|

|

Open web / Bowstring girder span |

130 mtr x 12 mtr |

|

|

Crane and Handling Facility |

||

|

Bay 1 |

EOT Crane in Shed 1: 25 MT – 3 no. / 20 MT – 1 no. Trial area under Goliath crane – 40 MT |

|

|

Bay 2 |

EOT Crane 15 mtr span – 4 no. |

|

|

Bay 3 |

EOT crane 25 mtr span – 2nos |

|

|

Blasting area |

Trolley – 30 MT – 2 nos + 2nos. 25 Mtr crane |

|

|

Painting Areao |

Mobile hydra - 15 mtr span- 30 MT – 6 no |

|

|

Mobile Handling |

4 nos Gen II Hydra - 15 MT |

|

|

Crawler Crane |

40 mt – 1no. on hire |

|

|

Machinery |

Capacity |

|---|---|

|

Oxy fuel Cutting Systems – 2 nos |

14 mtrs x 4 mtrs – 8 torch. 1200 MT/month x 2 |

|

HD Plasma cutting System – 3 nos |

24 mtr x 4 mtr |

|

Pug Cutting |

6 nos – 800 MT/month |

|

H beam/ Box Beam Formation |

1 no. line – 1500 MT fit up. |

|

Submerged Arc Welding for H Beam and Box Beam |

2 no. Gantry type 16 nos tractor type – Net 2000 MT /month |

|

GMAW Welding Stations |

30 nos |

|

Straightening Machine |

1 nos |

|

End Face Milling |

1 nos. |

|

High Speed Plate Drilling Machine |

2 nos – 2000 MT Drilling |

|

Core Cutters and Radial Drills |

15 nos / 4 nos |

|

Plate Bending Machine |

3.5 mtrs window. 3 mtrs long |

|

Pipe Bending Machine |

5 nos |

©Goodluck India Limited | All Rights Reserved

Designed by Web Cadence